Services on Demand

Journal

Article

Indicators

-

Cited by SciELO

Cited by SciELO

Related links

-

Similars in

SciELO

Similars in

SciELO

Share

Industrial Data

Print version ISSN 1560-9146On-line version ISSN 1810-9993

Ind. data vol.24 no.2 Lima July/Dec. 2021 Epub Dec 31, 2021

http://dx.doi.org/10.15381/idata.v24i2.19485

Production and Management

Application of Lean Manufacturing (5s and Kaizen) to Increase the Productivity in the Aqueous Adhesives Production Area of a Manufacturing Company

1Chemical Engineer from Universidad Nacional del Centro del Perú (Junin, Peru). Currently working as an independent consultant (Lima, Peru). E-mail: edith_luz91@hotmail.com

2Degree in Statistics from Universidad Nacional de Ingeniería (Lima, Peru). Currently teaches at the Escuela Profesional de Estadística of Universidad Nacional de Ingeniería (Lima, Peru). E-mail: jcameroj@uni.edu.pe

This research was conducted in a manufacturing company that has been experiencing a low-productivity problem for the last four years in the production area of aqueous adhesives, whose productivity values are lower than the expected value (5 kg/mh). Accordingly, a strategy for improvement based on the Lean Manufacturing methodology was considered necessary in this study, so the Kaizen methodology and the 5S were selected. This was carried out in stages that consisted, first, of a situational diagnosis, followed by the design, implementation and evaluation of the results. These stages were executed in 7 months, from January to July 2019. Upon application of the Lean Manufacturing methodology, the productivity results were evaluated and an average value of 5.58 kg/mh was obtained. It is worth mentioning that in 2018, before the application of Lean Manufacturing, the average productivity value was 4.37 kg/mh.

Keywords: Lean Manufacturing; productivity; 5S and Kaizen

INTRODUCTION

Aqueous adhesives are widely used as additives or intermediate products in different industries, such as the wood, paper, and bottling industries, among others. The emergence of new companies in this field is the result of an increasingly competitive market. Therefore, companies need to apply strategies that help them remain competitive and position themselves in the national market in order to survive as an industry, where not only quality is a determining factor, but also the improvement of the production system by eliminating activities that do not add value to the process or to the customer.

The manufacturing company under study, which manufactures aqueous adhesives, has to achieve certain objectives and goals, in addition to making the right decisions to ensure the company's permanence in the market and a high profitability that will result in benefits for its workers and shareholders; however, productivity has been low in the last 4 years. New methodologies based on process improvement, such as Lean Manufacturing, which increases productivity by eliminating waste, must be applied to reverse this situation.

The Lean Manufacturing methodology is defined as a management model of excellence and continuous improvement that focuses on the elimination of waste that does not add value to the product and is comprised of different tools. 5S and Kaizen tools were applied in this research, for which a literature review of Lean Manufacturing was undertaken, followed by the design, implementation and evaluation of the results with statistical methods.

The Lean philosophy is considered innovative and relevant within companies, since it allows optimizing production processes by eliminating activities that do not add value in the different stages of operations and that do not provide benefits to the company. This elimination is applied from the start to the end of production, which improves economy and saves resources.

Optimizing processes and improving productivity by reducing downtime translates into increased profits, improved product quality and a culture of change in people’s thinking, in order to achieve efficiency in the production process, that is, to produce more with fewer resources and less effort.

All production and service processes must be evaluated in order to generalize the results obtained to other organizations and identify where this methodology needs to be applied, essentially to provide solutions to problems through continuous improvement. Lean Manufacturing is implemented through six steps: formation of a Lean implementation team, training, diagnosis (identification of waste), Lean methodology application, analysis of results and elaboration of action plans focused on the reduction of process time to achieve cost reduction, defect reduction, improvement of the organization's profitability, among others.

Our general objective is “Apply Lean Manufacturing (5S and Kaizen) to increase productivity in aqueous adhesives production area of a manufacturing company”. Based on this, the specific objectives are “Analyze the current productivity situation of the aqueous adhesives production area of a manufacturing company”, “Apply the Lean Manufacturing methodology in the aqueous adhesives production area of a manufacturing company” and “Evaluate the productivity after applying the Lean Manufacturing methodology in the aqueous adhesives production area of a manufacturing company”.

JUSTIFICATION

The adhesives manufacturing sector is growing and is expected to make significant progress in the coming years, as it offers benefits such as equivalent and sometimes better performance than other products used in assembly and surface sealing, with advantages in terms of cost reduction. Adhesives are also used as intermediate products and inputs in a variety of industrial products, such as labeling adhesive, laminating adhesive (toilet paper), cardboard adhesive, among others; therefore, aqueous adhesives production has become an attractive business.

At present, the number of aqueous adhesive manufacturing companies offering quality products and services has increased, resulting in a competitive market. Therefore, this research focuses on applying an improvement strategy through Lean Manufacturing (5S and KAIZEN) and evaluating the impact on productivity growth.

THEORETICAL FRAMEWORK

Adhesives

Adhesive is defined as the application of all the forces that oppose the division of molecules of different contexts; therefore, adhesion is the resistance that opposes the separation of bodies (Bilurbina & Liesa, 1990).

Aqueous Adhesives

Water-based adhesives are solutions of polymers (of vegetable or synthetic nature) dissolved in water and are characterized by having a slower setting speed than solvent-based adhesives, since water takes longer to evaporate than organic adhesives (Gonzáles, 2014).

Water-based adhesives are one of the best alternatives to those using organic solvents, which are much more toxic and polluting (Gonzáles, 2014).

Lean Manufacturing

Lean Manufacturing is understood as the search for the improvement of the manufacturing system through the elimination or reduction of waste or muda, consisting of all actions that do not add value to the product or service produced by activities that consume resources without creating any value and for which customers are not willing to pay (Womack & Jones, 1996).

The Lean Manufacturing methodology aims to minimize waste on an ongoing basis to maximize process steps, focusing on cost reduction and minimization of waste and materials in the supply chain (Vinodh & Dino, 2012). This can be summarized in the following objectives:

Leverage the use of organizational assets;

Improve external and internal customer satisfaction;

Eliminate waste (activities that do not add value) in the manufacturing process.

The Pillars of Lean Manufacturing

Total Quality Control

Total quality control is quality assurance from the earliest stages of product development. It is designed to ensure that products or services meet quality requirements, which is accomplished involving all employees in all processes, thus giving rise to organization-wide quality control, considered to be the most important quality of Japanese quality control (Ishikawa, 1997).

Quality control is applied to an organization mainly to know the specifications set by the product engineering and to provide assistance to the manufacturing department, so that the production reaches these specifications. As such, it is concerned with the collection and analysis of large amounts of data that are then presented to different departments for subsequent evaluation.

Continuous Improvement

Continuous improvement is the permanent goal of organizations, as it focuses on problem solving. The PDCA cycle, today considered an essential improvement tool, was introduced by Deming, who described it in 4 steps (Socconini, 2018):

Plan: A change or test aiming at improvement.

Do: Test the change or test, preferably, on a small scale.

Check: Review the results - what have you learned?

Act: Adopt the change, abandon it, or go through the cycle again, possibly under different environmental conditions.

Just-In-Time (JIT)

Taiichi Ohno, executive vice president of Toyota Motor Corporation, developed the just-in-time production system seeking cost reduction through the elimination of waste. Based on concepts developed by Henry Ford and Walter Shewhart in the 1920s and 1930s, Ohno developed a philosophy of manufacturing excellence that surpassed all previous ones (Rajadell & Sánchez, 2010).

Productivity

Productivity is the correlation between production and the optimal use of financial, material and human resources to achieve organizational objectives, increase the quality of services and goods produced a pursue the development of employees (Rodríguez, 1999).

Effectiveness

Effectiveness is the ability of an organization to increase profits by different means, including the capacity to achieve the desired effect and the management of the inputs and outputs of the environment, such as politics and others (Fernández & Sánchez, 1997).

Efficiency

Efficiency is achieved when the objectives set are attained with the minimum amount of inputs. For instance, we can increase efficiency in a workday by eliminating breaks and reducing lunch time, which would increase production; however, it is possible that the number of errors will also increase due to employee fatigue, i.e., an efficient production system of inefficient products will have been achieved. Therefore, it is proposed that productivity is a relationship between effectiveness and efficiency achieved, monitoring manufacturing costs in which effectiveness is doing the right thing and efficiency is the way of doing things well (Huertas & Domínguez, 2015).

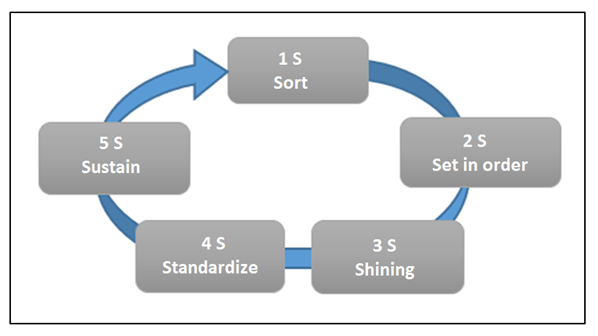

The 5 S:

The 5S are a methodology for improvement that originated in Japan. It consists of sorting, order and cleanliness of the area, standardization of processes and personnel discipline, so that they become habits in the work areas and a culture of labor improvement is achieved. This method can be applied to any field and in all work areas of a company (Barcia & Hidalgo, 2013)

Seiri: Sort. Determining and differentiating all that is really necessary or essential for our work area. Essential elements are kept, to later classify them while disposing of the unnecessary. Thus reducing elements at the workplace, and keeping only those essential to complete the processes and tasks with maximum effectiveness and efficiency (Aldavert, Vidal, & Lorente, 2017).

Seiton: Set in order. Placing what is necessary in an easily accessible place, placing useful things in order according to Safety/Quality/Efficiency criteria.

Safety: They should not fall, they should not move, they should not be in the way.

Quality: That They do not get hit, rust, mix or deteriorate.

Efficiency: Minimize lost time (Vargas, 2004).

Seiso: Shining. It intends to encourage the attitude of cleanliness of the work place and maintaining the classification and order of the elements. It should be supported by a strong training program and the supply of the necessary elements for its implementation, as well as the time required for its execution (Vargas, 2004).

Seiketsu: Standardize. Constantly maintaining the order, cleanliness and hygiene of the work area. It is achieved by cleaning regularly, keeping everything in its place and in order, establishing procedures and plans to maintain order and cleanliness (Vargas, 2004).

Shitsuke: Sustain. Getting into the habit of applying the 5 S’s in the work area, respecting and enforcing the rules of the work area, always using protective implements and maintaining cleanliness, so that they become daily habits (Vargas, 2004).

Kaizen:

The word Kaizen means “to improve”. When applied in organizations as a continuous improvement in the way of doing things, it generates an impact in the work place, as well as in the personal, family and social environment.

A culture of continuous improvement, which includes all workers, is a complementary effort towards performance improvement at all levels of the organization, directed towards the satisfaction of cross-functional goals such as quality, costs and human potential, in order to achieve greater customer satisfaction (Gil, Monzon, Celma, & Giner 1996).

There are 10 basic principles in the application of Kaizen, which resulted from various experiences in different Japanese companies. It became known that training and competence development of employees should encourage Kaizen culture development, where principles should be internalized and applied quite naturally.

According to Atehortua (2010), the Kaizen principles are:

Focus on customer requirements.

Constantly make small improvements.

Openly identify, recognize and address problems.

Encourage open communication.

Form “Kaizen” work teams.

Conduct Kaizen projects involving multi-functional individuals.

Maintain good working relationships.

Encourage self-discipline by means of recognition.

Maintain communication with employees.

Promote the development of competencies in all employees.

METHODOLOGY

Productivity Analysis

The values of the last 5 years are used for the productivity analysis (Table 1). Only in 2014, productivity exceeded the value of 5.00 kg/mh, which is the value expected by the manufacturing company.

Table 1 Productivity Results by Year.

| Year | Productivity kg/mh |

|---|---|

| 2014 | 5.23 |

| 2015 | 4.75 |

| 2016 | 4.60 |

| 2017 | 4.87 |

| 2018 | 4.37 |

Source: Prepared by the authors.

Productivity Determination

The following formula is used to determine productitvity in the company:

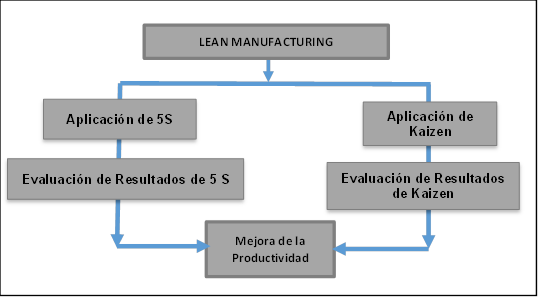

The methodology for the application of Lean Manufacturing 5 S and Kaizen is shown in Figure 2.

Selection of the Workteam

Production personnel and personnel from the continuous improvement area are selected to conduct and support the activities for the application of Lean Manufacturing tools (5S and Kaizen).

Training

The team selected is trained in Lean Manufacturing and the stages of its application; instructors from the Lean Six Sigma Institute of Mexico are in charge of training.

Assessment of the 5 S’s

An assessment of the current situation of the 5 S’s in the aqueous adhesives production area was carried out using a check list format to process the data. The images of the current situation are shown in Figure 3.

Source: Prepared by the authors.

Figure 3 Current situation of the aqueous adhesives manufacturing plant.

Application of the 5 S

The application consisted of following the guidelines of the 5S Implementation Handbook, provided by the Continuous Improvement area, which is summarized in the following steps:

Lay out elaboration (5S drawing). Delimitation of the zones or areas where the 5S are to be implemented.

Regarding 1S: A list of necessary items is created and unnecessary items are removed.

Regarding 2S: All the necessary items, including equipment, machines, furniture, tools, materials, among others, are located and labeled.

Regarding 3S: All necessary items are kept clean, a cleaning plan is implemented and compliance is monitored.

Regarding 4S: It is verified that labels and markings comply with the standardization rules set forth in the 5S Implementation Handbook.

Regarding 5S: 5S audits are carried out and a person responsible within the area is designated to address issues.

Application of Kaizen

Changes are made to improve the production process of the best-selling product through the implementation of a Kaizen. The implementation comprises the following stages.

The problem in the production process of aqueous adhesives is identified, which is the excessive manufacturing process time of the best-selling product.

The manufacturing process of the product is described, consisting of 10 stages in the production process.

A cause analysis is performed using the brainstorming and Pareto techniques. The root cause is the excessive cooling time of the reactor used in the manufacturing process due to lack of maintenance ( excessive scale build-up).

An action plan, including maintenance activities, is drafted in collaboration with the maintenance area of the equipment used in the production process.

The implemented activities are followed up and their effectiveness is evaluated.

Results of the 5 S

The results of the 5S diagnosis, carried out before the start of the Lean Manufacturing application in January 2018, are shown in Table 2 and in the images in Figure 4.

Table 2 Results of the 5S Assessment.

| Pillars of 5 S | Assessment of 5 S | |

|---|---|---|

| 1 S | Sort | 3.0 |

| 2 S | Set in order | 2.5 |

| 3 S | Shining | 2.7 |

| 4 S | Standardize | 2.2 |

| 5 S | Sustain | 3.5 |

| Average | 2.8 | |

Source: Prepared by the authors.

The results of the 5 S audit, conducted after applying the Lean Manufacturing methodology, in the months of April to July 2019, are shown in Table 3 and in Figure 5.

Table 3 Results of the 5 S Audit.

| Months (2019) | 5 S Audit Score | |

|---|---|---|

| 1 | April | 4.0 |

| 2 | May | 4.0 |

| 3 | June | 4.5 |

| 4 | July | 4.5 |

Source: Prepared by the authors.

Results Obtained from Kaizen

Table 4 shows the results of applying Kaizen to address the problem encountered (excessive manufacturing time of the product with the highest sales turnover); the application of Kaizen reduced manufacturing times by up to 2 hours and 23 minutes.

Table 4 Results of Applying Kaizen.

| Kaizen Tools | Months (2019) | Manufacturing Time (hours) |

|---|---|---|

| Before applying Kaizen | January | 20:15:00 |

| February | 20:04:00 | |

| March | 20:10:00 | |

| After applying Kaizen | April | 18:19:00 |

| May | 18:46:00 | |

| June | 17:26:00 | |

| July | 17:09:00 |

Source: Prepared by the authors.

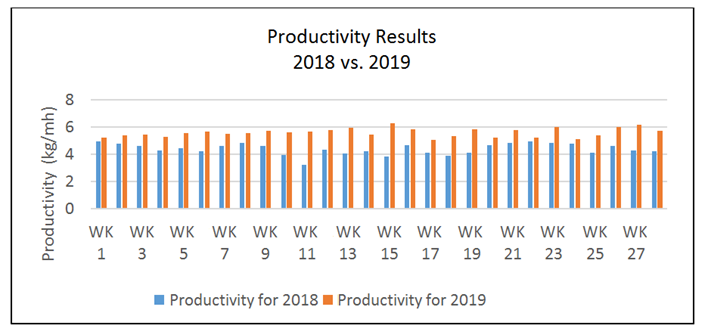

Productivity Data

Table 5 shows the productivity data obtained in the aqueous adhesives production area for 2018 (before applying the Lean Manufacturing methodology) and the productivity data for 2019 (after applying the Lean Manufacturing methodology).

Table 5 Productivity Data for 2018 and 2019.

| Month | Week | Productivity 2018 (kg/mh) | Productivity 2019 (kg/mh) |

|---|---|---|---|

| January | Week 1 | 4.93 | 5.20 |

| Week 2 | 4.75 | 5.35 | |

| Week 3 | 4.60 | 5.44 | |

| Week 4 | 4.25 | 5.24 | |

| February | Week 5 | 4.42 | 5.54 |

| Week 6 | 4.23 | 5.66 | |

| Week 7 | 4.60 | 5.48 | |

| Week 8 | 4.83 | 5.51 | |

| March | Week 9 | 4.62 | 5.72 |

| Week 10 | 3.93 | 5.61 | |

| Week 11 | 3.20 | 5.66 | |

| Week 12 | 4.30 | 5.75 | |

| April | Week 13 | 4.05 | 5.95 |

| Week 14 | 4.18 | 5.45 | |

| Week 15 | 3.84 | 6.25 | |

| Week 16 | 4.67 | 5.82 | |

| May | Week 17 | 4.12 | 5.06 |

| Week 18 | 3.85 | 5.34 | |

| Week 19 | 4.08 | 5.82 | |

| Week 20 | 4.63 | 5.19 | |

| June | Week 21 | 4.79 | 5.74 |

| Week 22 | 4.90 | 5.22 | |

| Week 23 | 4.83 | 5.97 | |

| Week 24 | 4.77 | 5.12 | |

| July | Week 25 | 4.10 | 5.36 |

| Week 26 | 4.58 | 5.98 | |

| Week 27 | 4.27 | 6.12 | |

| Week 28 | 4.19 | 5.69 | |

| Average | 4.37 | 5.58 |

Source: Prepared by the authors.

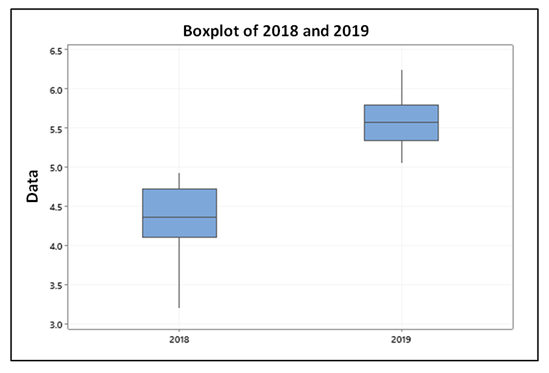

HYPOTHESIS TESTING

Pursuant to the hypothesis statement and the data shown in Table 5, Minitab software is used to evaluate the null hypothesis at a significance level of α = 0.05; Student’s t-test and the box plot are used to demonstrate whether the null hypothesis is accepted or rejected.

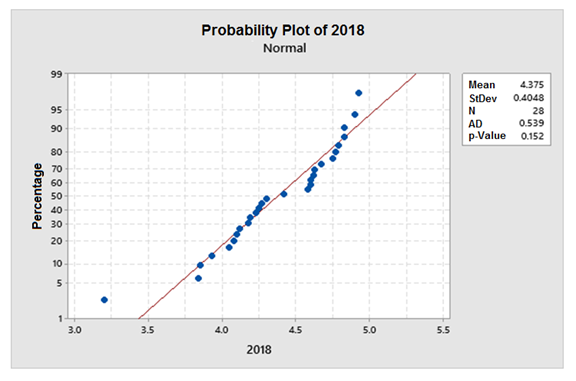

Statistical Normality Test

The Anderson Darling test is used for the statistical test of normality for the 2018 and 2019 productivity data. (Figure 7 and 8). The data were accepted as they had a p-value > α at 95% confidence.

Student’s t-Test

After determining that the data have a normal distribution, Student’s t-test is performed for both samples. Table 6 shows the result, where a p-value < α (0.00 < 0.05) was obtained; therefore, the null hypothesis is rejected and the alternative hypothesis is accepted. Consequently, productivity in 2019 is higher than productivity in 2018 due to the implementation of the Lean Manufacturing methodology.

Table 6 Results of Student's t-Test, Productivity of 2018 and 2019.

Source: Prepared by the authors.

Box Plot

The increase in productivity can be observed in the box plot in Figure 9.

DISCUSSION

Upon applying the Lean Manufacturing methodologies (5S and Kaizen), productivity results of the aqueous adhesives production area of a manufacturing company were improved. These results were corroborated via hypothesis testing. It was thus demonstrated that productivity increases upon applying Lean Manufacturing.

CONCLUSIONS

A baseline or diagnostic study of 5S was carried out before the application of Lean Manufacturing, obtaining an initial average value of 2.8. At the end of the 5S application, an average value of 4.03 was obtained as an audit result by reducing unnecessary time spent searching for materials and transporting personnel, in addition to improving the organization and cleanliness of the aqueous adhesives production area.

By applying the Kaizen methodology, the manufacturing process time of the product with the highest sales rate in the aqueous adhesives production area was reduced. Before applying Kaizen, the manufacturing time was 20:15 hours and, after the application, a manufacturing time of 17:09 hours was obtained, i.e., the manufacturing time was reduced by 3 hours and 6 minutes.

The results of the application of Lean Manufacturing can be used to improve productivity, sales rate, profitability, customer satisfaction, employees’ satisfaction and work environment in the manufacturing company under study.

ACKNOWLEDGMENT

To the industrial company that manufactures aqueous products for giving me the opportunity to participate in the implementation of this methodology. I would also like to thank the work team for their commitment and perseverance in meeting the objectives and achieving results.

REFERENCES

Aldavert, J., Vidal, E., y Lorente, J., y Adalvert, X. (2017). Guía Práctica 5 S para la Mejora Continua. La base del Lean. España: Alda Talent. [ Links ]

Atehortua, Y. (2010). Estudio y aplicación del Kaizen. ( Tesis de grado). Universidad Tecnológica de Pereira, Pereira. [ Links ]

Barcia, K., y Hidalgo, D. (2013). Implementación de una Metodología con la Técnica 5S para Mejorar el Área de Matricería de una Empresa Extrusora de Aluminio. Revista Tecnológica - ESPOL, 18(1), 69-75. Recuperado de http://www.rte.espol.edu.ec/index.php/tecnologica/article/view/226/ [ Links ]

Bilurbina, L., y Liesa, F. (1990). Materiales no metálicos resistentes a la corrosión. Barcelona, España: Marcombo S.A. [ Links ]

Fernández, R., y Sánchez, C. (1997). Eficacia Organizacional. Concepto, desarrollo y evaluación. Madrid, España: Ediciones Díaz de Santos [ Links ]

Gil, M., Monzon, J., Celma, M., y Giner, F. (1996). Cómo crear y hacer funcionar una empresa: casos prácticos. Madrid, España: ESIC Editorial. [ Links ]

González, F. (2014). Materiales y servicios en reparación de calzado y marroquinería. Madrid, España: IC Editorial. [ Links ]

Huertas, G., y Domínguez, G. (2015). Decisiones estratégicas para la dirección de operaciones en empresas de servicios y turísticas. Barcelona, España: Publicacions i Edicions de la Universitat de Barcelona. [ Links ]

Ishikawa, K. (1997). ¿Qué es el control total de calidad? Bogotá, Colombia: Editorial Norma. [ Links ]

Rajadell, M., y Sánchez, J. (2010). Lean Manufacturing, la evidencia de una necesidad. Madrid, España: Ediciones Díaz de Santos. [ Links ]

Rodríguez, C. (1999). El nuevo escenario. La cultura de calidad y productividad en las empresas. Jalisco, México: ITESO. [ Links ]

Socconini, L. (2018). Lean Manufacturing. Paso a Paso.Barcelona, España: Marge Books. [ Links ]

Vargas, R. (2004). Manual de Implementación Programa 5S. Santander, Colombia: Corporación Autónoma. [ Links ]

Vinodh, S. y Dino, J. (2012). Structural Equation Modelling of lean manufacturing practices.International Journal of Production Research , 50(6), 1598-1607. Recuperado de https://doi.org/10.1080/00207543.2011.560203 [ Links ]

Womack, J. y Jones, D.(1996). Lean Thinking. Barcelona, España: Gestión 2000. [ Links ]

Received: February 01, 2021; Accepted: October 28, 2021

text in

text in