Services on Demand

Journal

Article

Indicators

-

Cited by SciELO

Cited by SciELO

Related links

-

Similars in

SciELO

Similars in

SciELO

Share

Industrial Data

Print version ISSN 1560-9146On-line version ISSN 1810-9993

Ind. data vol.25 no.2 Lima July/Dic. 2022

http://dx.doi.org/10.15381/idata.v25i2.22769

Production and Management

Ergonomic Method to Reduce the Risk Level of Musculoskeletal Disorders in a Garment Manufacturing SME in Lima, Peru

6 Mechatronics engineer from UNI and PhD in Business Management from UNMSM. Currently working as associate professor and postgraduate professor at the School of Industrial Engineering - UNMSM. (Lima, Peru). E-mail: jortizp@unmsm.edu.pe

2Industrial Engineering student at UNMSM (Lima, Peru). E-mail: andrei.bancovich@unmsm.edu.pe

3Industrial Engineering student at UNMSM (Lima, Peru). E-mail: taddy.candia@unmsm.edu.pe

4 Textile and Apparel Engineering graduate from the School of Industrial Engineering at UNMSM (Lima, Peru). Currently working as an independent consultant (Lima, Peru). E-mail: lisseth.huayanay@unmsm.edu.pe

5 Industrial engineer from UNMSM and Master’s Degree in Industrial Engineering from UNMSM (Lima, Peru). Currently working as main professor and Academic Vice-Dean of the School of Industrial Engineering - UNMSM (Lima, Peru). E-mail: lraezg@unmsm.edu.pe

In Peru, the textile industry represents a very important sector due to its significant contribution to the national GDP. All 398 thousand workers in this sector are prone to suffer from musculoskeletal disorders (MSDs), since the operation of machinery and handling of materials involves prolonged repetitive movements, causing strain on the body. This research aims to reduce the risk level of MSDs in a garment manufacturing SME. Therefore, an ergonomic method was developed based on REBA and RULA integration, which also proposes preventive and corrective measures. A initial evaluation was performed based on the observed postures of the operators to identify the risk levels; subsequently, the evaluation was repeated upon the implementation of the method in order to estimate its effectiveness. As a result, there was an improvement of 44.97%, that is, the level of risk to which the workers are exposed was reduced, demonstrating that the method is useful for garment manufacturing SMEs.

Keywords: musculoskeletal disorders (MSDs); risk level; REBA; RULA; ergonomic method.

INTRODUCTION

In the textile industry, manufacturing jobs require coordination and considerable effort on the part of the workers (Ministry of Economy and Finance, 2016). During the workday, operators perform repetitive and invariable operations using their hands and feet. They remain in awkward and extreme positions for their joints: arching the back, raising the shoulders, bending the neck, extending the wrists and bending the arms and legs. To avoid downtime, operators are often deprived of being able to stretch their limbs (De la Cruz et al., 2017). This overexertion of manufacturing workers gives rise to multiple musculoskeletal disorders (MSDs), which mainly affect the back, neck, shoulders and upper and lower extremities, as well as causing damage to joints and/or other tissues. MSDs can manifest as pain and discomfort and, in the most severe cases, require medical attention. For chronic disorders, injuries are irreversible and cause disability, leading to an inability to work, thus causing damage to the workers and considerable costs to the company (Puig et al., 2020). Five percent of all deaths worldwide are due to occupational diseases and work-related accidents, of this 5%, 86.3% is due to work-related diseases and the remaining 13.7% is due to fatal accidents (Hämäläinen et al. 2017).

The reduction of musculoskeletal disorders is achieved through the improvement of postural habits in textile workshop operators. For example, in their paper Prevención de Trastornos Musculoesqueléticos mediante la mejora de Hábitos Posturales: experiencia en el colectivo de limpieza, Puig et al. (2020) aim to improve posture in the work environment of the cleaning sector, in order to prevent musculoskeletal disorders. Likewise, Buendia (2018) in his article Los trastornos musculoesqueléticos en trabajadores de una empresa textil de Lima aims to determine musculoskeletal disorders (MSDs) in workers of a textile company and the frequency with which they occur. To this end, a descriptive study was conducted in a textile company dedicated to the manufacture, production and export of cotton knitwear garments. Gonzales (2019), in his thesis entitled Propuesta de un método de prevención de riesgos disergonómicos en un taller de confecciones para reducir los sobreesfuerzos de los operarios, proposes a method of risk prevention applied to a sewing workshop to reduce musculoskeletal disorders, preventing employees from developing health problems. Then, through some ergonomic methods such as OCRA (occupational repetitive action) and REBA (rapid entire body assessment), an analysis of the postures that result in the level of ergonomic risk in workers is performed; upon identifying the most affected areas of the worker, recommendations are made to correct postures, redesign the work environment and acquire ergonomic equipment. Finally, the research by Miranda and Sáenz (2020) aims to design a method to reduce MSDs and the number of hours of absence from work, as some of them are related to MSDs, through the use of observational techniques such as RULA, REBA or NIOSH.

This research study was conducted in a textile manufacturing SME located in the district of Lima, Peru, engaged in the manufacture of knitted garments, mostly t-shirts and jackets. As a result of constant complaints about physical ailments from workshop operators, the company decided to perform an ergonomic evaluation to identify the causes of the problem. Therefore, the objective of the research was to develop and implement an ergonomic method to reduce the risk level of MSDs, validated by means of statistical tools, such as the Anderson-Darling normality test and Student’s t-test, which yielded satisfactory factors that contrasted the hypothesis, that is, a significant reduction in the risk level of MSDs before and after the implementation of the ergonomic method developed.

This paper aims to contribute to the scientific community by providing an ergonomic method based on the REBA-RULA integration modeled using the Ergoniza software tool to be implemented in the garment industry. The hypothesis testing and the results obtained validate the proposed method; therefore, we recommend exploring its use in similar contexts in order to improve its practical value as an alternative for future research.

Musculoskeletal Disorders

Musculoskeletal disorders (MSDs) are a group of inflammatory and degenerative conditions, which are a direct consequence of repetitive movements, heavy lifting, prolonged static postures, awkward postures, etc. MSDs mainly affect the soft parts of the musculoskeletal system: muscles, tendons, nerves, ligaments and joints, and cause discomfort and pain in the affected areas. In contrast to other types of injuries which also occur in the workplace, MSDs demand longer recovery time and cause substantial lost workdays (Nabi et al., 2021). In the Iranian textile industry, MSDs are recognized as a highly prevalent problem, specifically in spinning, tasks with repetitive movements, overhead and shoulder activity, handling of heavy loads, among others, are observed, causing pain in the shoulder, neck, hands, as well as in the lumbar and thoracic areas (Shahbazi et al., 2020). In Latvia, the textile industry is made up of approximately 12 000 people, studies indicate that workers suffer MSDs caused not only by physical loads, but also by mental effort, work precision and visual fatigue (Kalkis et al., 2020).

Prevention of Musculoskeletal Disorders

Workers in the textile industry are exposed to awkward postures, repetitive work and constant handling of materials; to avoid the risk factors associated with MSDs, it is suggested that an adequate environment for workers to rest, as well as training programs that promote safety at work, be implemented (Hossain et al., 2018).

Sakthi Nagaraj et al. (2019) recommend performing stretching routines and designing work areas ergonomically. Likewise, Barbosa et al. (2022) propose robotic collaboration, i.e., encouraging robot-human collaboration to eliminates monotonous, dangerous and repetitive work. Job rotation is also recommended, as it prevents overloading certain body parts by alternating jobs with different types of risk levels.

Posture

According to Litardo et al. (2020), the term “posture” refers to the position adopted by each part of the body in relation to adjacent segments and to the body as a whole. Neutral posture is the best position for the human body, as it reduces stress and provides greater control and strength. In this position the body exerts less pressure on the joints, tendons, muscles and nerves; moreover, the muscles are in an ideal position, as they are neither contracted nor stretched. In summary, neutral posture is one that provides a proportionate alignment of body landmarks (Stack et al., 2016).

Ergonomics

Ergonomics is a field of science based on the application of knowledge related to the biomechanical, physiological and psychological capacities and limitations of the human being. The knowledge acquired is used to plan, design and evaluate work areas, tools and equipment to increase the performance and health of a company’s workers. In short, ergonomics adjusts workplaces for employee comfort to prevent MSDs through the identification, evaluation, and control of risk factors related to workplaces (Stack et al., 2016).

Risk Factors Associated with MSD

Risk factors are those factors that, due to high exposure or intensive presence, which can be of organic, physical, psychological or social origin, lead to the development of MSDs. Historically, force, posture, repetitiveness and insufficient rest were catalogued as the most common risk factors (Instituto Nacional de Seguridad y Salud en el Trabajo, 2019). According to Siddiqui et al. (2021), heat, noise, light, odor and dust should also be considered risk factors as they contribute to the development of MSDs.

Personal Risk Factors

Personal risk factors also contribute to the occurrence of injuries in the work area, for instance, age influences the body’s recovery process. Duration is another relevant factor. The gender of the worker is also taken into account due to hormonal and anatomical differences, hobbies, obesity, previous injuries and pregnancy are also considered relevant (Stack et al., 2016).

In West Bengal, handloom weavers suffer from low back pain, which was directly related to the number of years of work. Similarly, in Varanasi, workers in the same sector suffer from MSD which is caused by age and years of service (Siddiqui et al., 2021).

Force

Force refers to the amount of physical effort required to perform an activity or movement. Any activities that require greater force increase the mechanical loads on the muscles, joints and tendons. Also, if there are risk factors involved, such as vibration or speed, the force required to perform the movements also increases, quickly leading to fatigue at times (Stack et al., 2016).

Awkward or Unsupported Postures

Awkward or unsupported postures are non-neutral positions that, being unsupported, force the limits of the body, compressing the nerves and irritating the tendons. Awkward postures increase the risk of MSDs because they demand greater strength and cause fatigue, because the body is actively working to maintain the posture. The greater the difference in posture from neutral, the greater the risk of injury (Stack et al., 2016).

Static Postures

Static postures are those maintained for prolonged periods of time, which prevent adequate blood flow. The effort required to maintain a static posture puts an increased load on the tendons and muscles, causing fatigue. Blood flow transports nutrients to the muscles and removes waste products. As waste products accumulate due to muscle contraction, fatigue ensues, which is a precursor to injury (Stack et al., 2016).

Repetitive Movements

Repetitive movements are a risk factor, because the same movement or group of actions is executed repeatedly. They occur when the same set of muscles is used, thus muscles do not rest and are overused. Repetition is not a problem of great magnitude; however, it should be carefully considered when combined with other risk factors (Stack et al., 2016).

REBA-RULA Integration

The Rapid Entire Body Assessment (REBA) method was jointly developed by a group of ergonomists, nurses and physiotherapists after identifying and analyzing approximately 600 different postures. REBA method allows for the joint analysis of the upper limbs, which include the wrist, forearm and arm, as well as the neck, trunk and lower limbs. The advantage of this method is that muscle activity and grip type are both included in the analysis. REBA considers five (5) levels of risk, ranging from “negligible” to “very high”. An important prerequisite for this evaluation is the worker’s permission, since evaluators must obtain the relevant information about the work performed. Evaluators can conduct observation directly or by recording videos and taking photographs (Hita et al., 2020).

The Rapid Upper Limb Assessment (RULA) method was designed by McAtamney and Corlett in 1993 with the aim of identifying the risk factors to which the upper limbs of workers are exposed during work activities. The factors considered in this method are posture of the body areas, the load exerted and the muscle activities, including repetitive movements and static posture. RULA focuses on a specific body region, which is divided into two groups: Group A (wrist, wrist rotation, arm and forearm) and Group B (legs, neck and torso). This method has four (4) levels of action, ranging from “no action needed” to “urgent measures needed” (Gómez et al., 2020).

As mentioned above, REBA performs an analysis of the whole body taking into account muscle activity and the type of grip. In contrast, RULA focuses only on the upper limbs, considering body posture, force exerted, repetitive movements and static posture. The joint use of these two evaluation methods to analyze the risk factors associated with MSDs in the textile industry is extremely important, as they suppress each other’s limitations and complement each other’s results. Since REBA has a general approach and RULA is more specific, a successful integration of these two methods provides a broader picture and more accurate information, which contributes to making better recommendations for addressing MSDs.

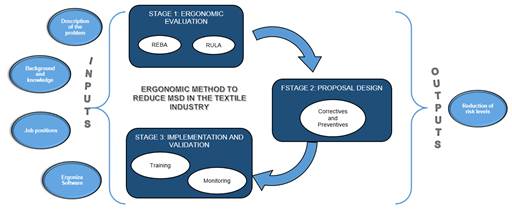

Ergonomic Method in Garment Companies

The method designed in this study is based on the integration of ergonomic techniques to reduce the risk of MSDs in the operators of the garment manufacturing SME after implementing preventive and corrective measures. Figure 1 shows the proposed method. The contribution of REBA and RULA methods consists of assessing the situation before and after the improvements and comparing the scores obtained to identify the results.

METHODOLOGY

For this study a methodology based on induction-deduction was developed and descriptive quantitative techniques were used in order to measure and evaluate potential risk factors that negatively affect health and performance of operators. Based on ergonomic concepts found in the literature and the observational ergonomic techniques in conjunction with the Ergoniza software, the study attempted to develop an ergonomic method to reduce the risk of garment manufacturing SME employees suffering MSDs.

Observational ergonomic techniques were used to estimate and evaluate the level of risk in the sewing station; questionnaires were used to identify possible causes of MSDs in the area and a risk matrix was developed to categorize their severity.

The research design is experimental, since the variables are manipulated and the phenomena are perceived in their natural state for subsequent analysis.

The population consisted of the 12 operators working in the sewing station. For the purpose of reducing the impact of error, the entire population was used as a sample. The sample was nonetheless calculated in order to validate the decision, resulting in 12 units.

Direct observation was used to select the activities for the ergonomic study, and the REBA and RULA questionnaires provided by the Ergoniza software were also applied to evaluate the risk of operators suffering MSDs.

The first step was to visit the SME sewing workshop. A project plan was created detailing the economic activity, organization, personnel distribution, operations, position and classification of the operators. An ergonomic evaluation was then conducted using the REBA and RULA methods through the Ergonautas software to speed up the evaluation process and obtain immediate results.

After determining the level of action and the severity of the case, a series of corrective and preventive measures were proposed to reduce the risk of operators developing MSDs.

Following the implementation of measures, the evaluation was performed again using the REBA and RULA methods, the results were recorded and a comparative graph was made. Subsequently, an Anderson-Darling test was performed to identify whether the data collected in the evaluations followed a normal distribution; upon identifying that they were indeed normal data, a Student’s t-test for two samples was performed. The values obtained contrasted the hypothesis: a significant reduction in the risk level of MSDs before and after the implementation of the ergonomic method developed.

RESULTS

Ergonomic Assessment

Evaluation Using REBA

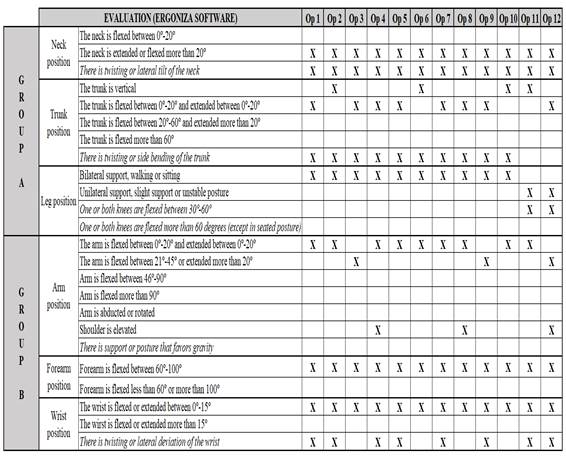

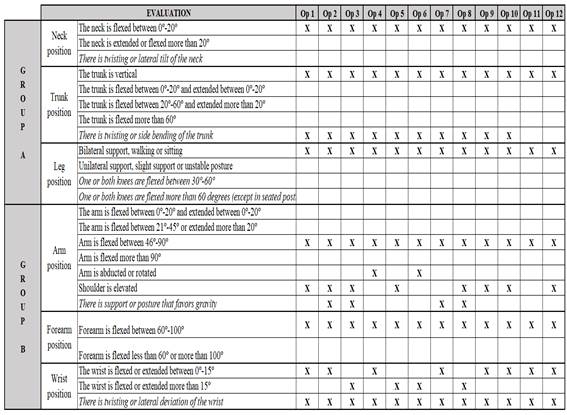

The first evaluation was conducted on the operators of the sewing workshop according to their positions (Table 1), using the REBA method with the Ergoniza software. The questions shown in Table 2 were answered following the observation.

Table 1 List of Activities per Operator in the Sewing Workshop.

| Position | Function | Description |

|---|---|---|

| Operator No. 1 | Cutting pieces | Work performed seated |

| Operator No. 2 | Sewing | Work performed seated |

| Operator No. 3 | Sewing | Work performed seated |

| Operator No. 4 | Sewing | Work performed seated |

| Operator No. 5 | Sewing | Work performed seated |

| Operator No. 6 | Sewing | Work performed seated |

| Operator No. 7 | Sewing | Work performed seated |

| Operator No. 8 | Sewing | Work performed seated |

| Operator No. 9 | Sewing | Work performed seated |

| Operator No. 10 | Sewing | Work performed seated |

| Operator No. 11 | Cutting excess material | Work performed standing |

| Operator No. 12 | Cutting excess material | Work performed standing |

Source: Prepared by the authors.

The levels of risk obtained after entering the information requested by the Ergoniza software are shown in Table 3, evidencing the risk of MSDs faced by the operators of the sewing workshop under study.

Table 3 Level of Risk in The Sewing Workshop Obtained by the RULA Method.

| Position | Score | Level | Risk |

|---|---|---|---|

| Operator No. 1 | 7 | 2 | Medium |

| Operator No. 2 | 6 | 2 | Medium |

| Operator No. 3 | 6 | 2 | Medium |

| Operator No. 4 | 7 | 2 | Medium |

| Operator No. 5 | 8 | 3 | High |

| Operator No. 6 | 5 | 2 | Medium |

| Operator No. 7 | 4 | 2 | Medium |

| Operator No. 8 | 6 | 2 | Medium |

| Operator No. 9 | 7 | 2 | Medium |

| Operator No. 10 | 6 | 2 | Medium |

| Operator No. 11 | 6 | 2 | Medium |

| Operator No. 12 | 8 | 3 | High |

Source: Prepared by the authors.

Upon obtaining the score and risk level of each operator, the performance level according to Ergoniza was reviewed as shown in Table 4.

Table 4 Action Level Obtained Using REBA.

| Score | Level | Risk | Action |

|---|---|---|---|

| 1 | 0 | Negligible | No action is needed |

| 2 o 3 | 1 | Low | Measures may be required |

| 4 a 7 | 2 | Medium | Action is required |

| 8 a 10 | 3 | High | Action is required promptly |

| 11 a 15 | 4 | Very high | Immediate action is required |

Source: Prepared by the authors, adapted from Ergoniza.

Evaluation using RULA

The evaluation was conducted using the RULA method with the information requested by the software, which is shown in Table 5.

The results obtained upon entering the data in the software are shown in Table 6.

Table 6 Level of Risk in The Sewing Workshop Obtained by the RULA Method.

| Position | Score | Level | Action |

|---|---|---|---|

| Operator No. 1 | 7 | 4 | Urgent task changes are required |

| Operator No. 2 | 5 | 3 | Redesign of the task is required |

| Operator No. 3 | 5 | 3 | Redesign of the task is required |

| Operator No. 4 | 7 | 4 | Urgent task changes are required |

| Operator No. 5 | 7 | 4 | Urgent task changes are required |

| Operator No. 6 | 4 | 2 | Changes to the task may be required; further study is recommended |

| Operator No. 7 | 4 | 2 | Changes to the task may be required; further study is desirable |

| Operator No. 8 | 5 | 3 | Redesign of the task is required |

| Operator No. 9 | 7 | 4 | Urgent changes in the task are required |

| Operator No. 10 | 5 | 3 | Redesign of the task is required |

| Operator No. 11 | 6 | 3 | Task changes may be required; further study is recommended |

| Operator No. 12 | 7 | 4 | Urgent task changes are required |

Source: Prepared by the authors.

Following the results, the level of risk was analyzed with the information obtained from Ergoniza, which is shown in Table 7.

Improvements and Hypothesis Testing

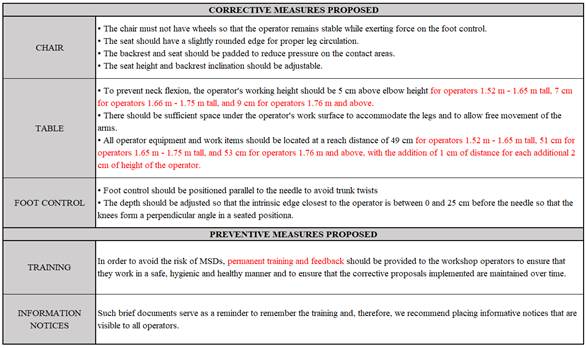

Upon obtaining the results of the ergonomic evaluation, a series of corrective and preventive measures were devised to reduce the latent risk of MSDs, as shown in Table 8.

Table 8 Corrective and Preventive Proposals in the Sewing Workshop.

Source: Prepared by the authors.

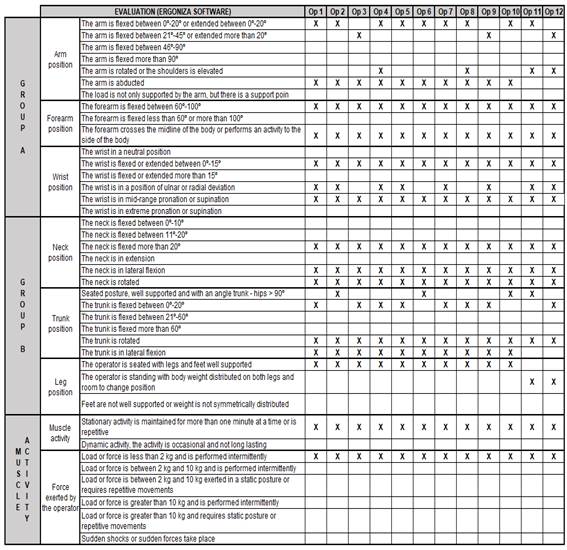

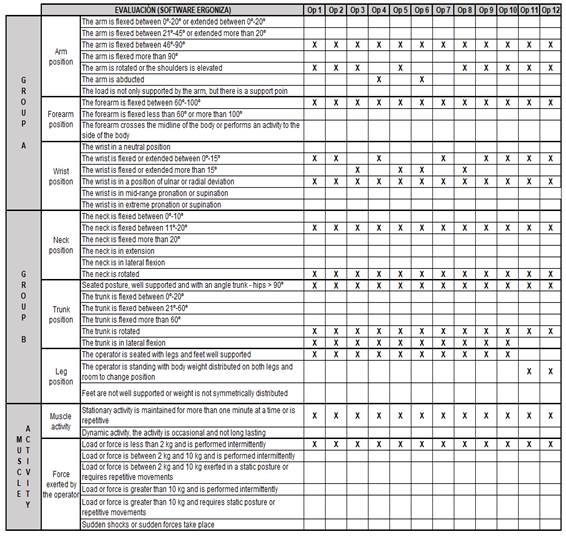

Upon implementing of the corrective and preventive proposals, the second evaluation was conducted on the workshop operators using the REBA method with the Ergoniza software. The questions shown in Table 9 were answered following the observation.

Table 9 REBA Ergonomic Evaluation in the Sewing Workshop upon Implementing the Preventive and Corrective Measures.

Source: Prepared by the authors.

Following the second evaluation, the risk levels shown in Table 10 were obtained via Ergoniza software.

Table 10 Risk Level in the Sewing Workshop upon Implementing the Preventive and Corrective Measures Obtained Using REBA.

| Position | Score | Level | Risk |

|---|---|---|---|

| Operator No. 1 | 4 | 2 | Medium |

| Operator No. 2 | 3 | 1 | Low |

| Operator No. 3 | 3 | 1 | Low |

| Operator No. 4 | 4 | 2 | Medium |

| Operator No. 5 | 4 | 2 | Medium |

| Operator No. 6 | 4 | 2 | Medium |

| Operator No. 7 | 2 | 1 | Low |

| Operator No. 8 | 3 | 1 | Low |

| Operator No. 9 | 4 | 2 | Medium |

| Operator No. 10 | 4 | 2 | Medium |

| Operator No. 11 | 2 | 1 | Low |

| Operator No. 12 | 3 | 1 | Low |

Source: Prepared by the authors.

Similarly, following the implementation of the improvements, the evaluation was conducted using the RULA method. The results are shown in Table 11.

Table 11 RULA Ergonomic Assessment in the Sewing Workshop after Implementing Preventive and Corrective Measures.

Source: Prepared by the authors.

Following the second evaluation, the risk levels shown in Table 12 were obtained via Ergoniza software.

Table 12 Risk Level in the Sewing Workshop upon Implementing the Preventive and Corrective Measures Obtained Using RULA.

| Position | Score | Level | Action |

|---|---|---|---|

| Operator No. 1 | 3 | 4 | Task changes may be required; further study is recommended |

| Operator No. 2 | 2 | 3 | Acceptable risk |

| Operator No. 3 | 2 | 3 | Acceptable risk |

| Operator No. 4 | 3 | 4 | Task changes may be required; further study is recommended |

| Operator No. 5 | 3 | 4 | Task changes may be required; further study is recommended |

| Operator No. 6 | 3 | 2 | Task changes may be required; further study is recommended |

| Operator No. 7 | 2 | 2 | Task changes may be required; further study is recommended |

| Operator No. 8 | 3 | 3 | Task changes may be required; further study is recommended |

| Operator No. 9 | 4 | 4 | Task changes may be required; further study is recommended |

| Operator No. 10 | 4 | 3 | Task changes may be required; further study is recommended |

| Operator No. 11 | 2 | 3 | Acceptable risk |

| Operator No. 12 | 3 | 4 | Task changes may be required; further study is recommended |

Source: Prepared by the authors.

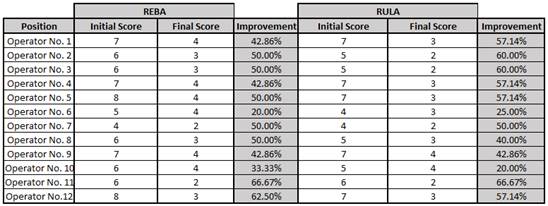

To determine the effectiveness of the proposed ergonomic method, we measured the improvement comparing the scores obtained in the first and second evaluations. For this purpose, the RE (reduction of MSDs) indicator was used, calculated using the following formula:

RE = (Initial score - Final score) / Initial score *100%

After calculating the geometric mean, it was concluded that the risk of developing MSDs was reduced by approximately 44.97%.

Hypothesis Testing

The research question was “Is the ergonomic method able to reduce the risk of MSDs in a textile manufacturing SME?” In response to this question, the following general hypothesis was formulated:

H0 = There is no significant change in MSD risk reduction before and after the implementation of the ergonomic method.

Ha = There is significant change in MSD risk reduction before and after the implementation of the ergonomic method.

A normality test was conducted before and after implementing the improvements to determine whether the data collected followed a normal distribution. Statistical software MINITAB 2018 was used for this purpose, and the normality of the data was tested using an Anderson-Darling test at a significance level of 5%.

P value ≤ α, data follow a normal distribution

P value > α, data do not follow a normal distribution

The normality test yielded a p-value of 0.161, a value higher than the significance coefficient, demonstrating that the data have a normal distribution. Upon determining the distribution of the data, the pertinent statistical test was performed.

The Student’s t-test yielded a t-value of 7.46 and a p-value of 0.0000.

As the t value is greater than the p value, H0 is rejected and Ha is accepted; therefore, there is a significant change in MSD risk reduction before and after the implementation of the ergonomic method in the textile industry. The method complies with its main objective.

DISCUSSION

Each year, the textile industry accounts for 2% of the world’s gross domestic product (GDP) and creates 57 million jobs globally. In Latin America, the percentage of spending on footwear and apparel is expected to increase by 7.2% in the next five years. In Peru, regarded as the largest apparel exporter in South America, the textile industry remains highly relevant. Its relevance derives from its contribution to the national GDP, given that the manufacturing sector, of which it is a part, contributes 12.5%; the textile sector, in turn, contributes 7.9%. The likelihood of MSDs is very high in this industry due to the handling of machinery and materials, as prolonged repetitive and straining movements are performed on the body. This is aggravated by the number of workers in this industry, which amounts to 398 thousand people nationwide (Quiroz et al., 2021).

Several different types of ergonomic evaluations are used to reduce the occurrence of such conditions, among which are RULA and REBA. The REBA method performs a general evaluation of the human body, in other words, it performs an analysis of all the regions of the body taking into account the muscle activity and the type of grip (Hita et al., 2020). The RULA method, on the other hand, focuses only on the upper limbs considering body posture, force exerted, repetitive movements and static posture (Gómez et al., 2020).

This research study aimed to reduce the occurrence of MSDs in a garment manufacturing SME in Lima, Peru; for this purpose, an ergonomic method was developed based on the integration of the REBA and RULA methods. This method combines ergonomic techniques and proposes preventive and corrective measures. Furthermore, the integration of these two evaluations reduces each other’s limitations, thus providing a broader picture and more accurate information.

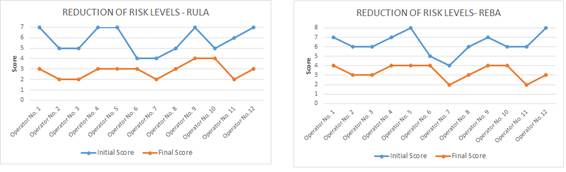

Following the application of the developed method, a considerable reduction in the risk of MSDs in the sewing workshop was achieved; the numerical results show an overall reduction of 44.97%; the comparative results can be seen in Figure 2. These results are consistent with Miranda and Sáenz (2020), who used RULA, REBA and NIOSH ergonomic evaluations, and achieved a reduction of 44.42% of the MSDs in the Overlock, Spreading and Roll Supply areas.

Source: Prepared by the authors.

Figure 2 A comparison of the risk levels before and after implementing the corrective and preventive proposals.

In order to prevent MSDs, we attempted to replace the furniture (tables and chairs) with more ergonomic options; however, due to the insufficient budget, the existing furniture was simple adapted, resulting in an improvement for the operators. A daily active rest plan was also implemented.

This research study posed two hypotheses: the null hypothesis (H0) stating that there is no significant difference between the risk reduction of MSDs before and after implementing the ergonomic method; and the alternative hypothesis (Ha) stating that there is a significant difference between the risk reduction of MSDs before and after implementing the ergonomic method. Both hypotheses were contrasted by means of a Student’s t-test, which rejected the H0 and it was concluded that there is a reduction in the risk levels after implanting the ergonomic method and that the work complies with the proposed objective.

CONCLUSIONS AND RECOMMENDATIONS

The use of REBA and RULA is recommended due to their ability to score MSD risk levels in the work environment, for which reason an ergonomic method based on the integration of both methods was developed in this research study; preventive and corrective measures were also proposed. The purpose of this research was to reduce the risk level of MSDs in a garment manufacturing SME. The results show that there is a significant difference in the initial and final score of the risk levels after the implementation of the ergonomic method based on the REBA-RULA integration, as it dropped from a “high” to a “medium” or “low” risk level. The likelihood of MSDs among workers in the garment manufacturing SME was reduced by 44.97%. The proposed corrective and preventive recommendations were proved to be effective, as the results show that the risk of injury decreased. In conclusion, the ergonomic method is feasible because it met the objective: to reduce the risk level of MSDs in a garment manufacturing SME.

The proposed ergonomic method, however, was specifically designed for the context described in the study. As an alternative for future research, it is recommended to explore its feasibility in similar and not so similar environments, such as other industries or larger garment companies, as the literature shows that the risk of MSDs is latent in all industries and sectors. It is also recommended to integrate modern ergonomic prevention tools to the method in order to update its practical value.

REFERENCIAS

Barbosa, J., Carneiro, P., y Colim, A. (2022). Ergonomic Assessment on a Twisting Workstation in a Textile Industry. En Studies in Systems, Decision and Control: Occupational and Environmental Safety and Health III Vol. 406 (pp. 411-419). https://doi.org/10.1007/978-3-030-89617-1_37 [ Links ]

Buendia, J. (2018). Trastornos musculoesqueléticos en trabajadores de una empresa textil de Lima. Rev. Peru. salud pública comunitaria, 1(2), 66-70. https://1library.co/document/z319488y-trastornos-musculoesqueleticos-trabajadores-empresa-textil-lima.html [ Links ]

De la Cruz, N., y Viza, G. (2017). Factores de riesgos ergonómicos que inciden en la salud de los trabajadores del área de producción de la Empresa Andes Yarn S.A.C., Arequipa - 2016. (Tesis de pregrado). Universidad Nacional de San Agustín de Arequipa, Arequipa. http://repositorio.unsa.edu.pe/handle/UNSA/3773 [ Links ]

Gómez, M., Callejón, Á. J., Pérez, J., Díaz, M., y Carrillo, J. A. (2020). Musculoskeletal Risks: RULA Bibliometric Review. International Journal of Environmental Research and Public Health, 17(12), 1-52. https://doi.org/10.3390/ijerph17124354 [ Links ]

Gonzales, K. W. (2019). Propuesta de un modelo de prevención de riesgos disergonómicos en un taller de confecciones para reducir los sobreesfuerzos de los operarios. (Tesis de pregrado). Universidad Nacional Mayor de San Marcos, Lima. https://cybertesis.unmsm.edu.pe/handle/20.500.12672/11429 [ Links ]

Hämäläinen, P., Takala, J., y Kiat, T. B. (2017). Global estimates of occupational accidents and work-related illnesses 2017.World,2017, 3-4. [ Links ]

Hita, M., Gómez, M., Díaz, M., y Callejón, Á. J. (2020). An overview of reba method applications in the world. In International Journal of Environmental Research and Public Health, 17( 8), 2635. https://doi.org/10.3390/ijerph17082635 [ Links ]

Hossain, M. D., Aftab, A., Al Imam, M. H., Mahmud, I., Chowdhury, I. A., Kabir, R. I., y Sarker, M. (2018). Prevalence of Work Related Musculoskeletal Disorders (WMSDs) and Ergonomic Risk Assessment Among Readymade Garment Workers of Bangladesh: A Cross Sectional Study. PLoS ONE, 13(7). https://doi.org/10.1371/journal.pone.0200122 [ Links ]

Instituto Nacional de Seguridad y Salud en el Trabajo. (2019). Factores de riesgo para los TME. https://www.insst.es/-/factores-de-riesgo-para-los-t-1 [ Links ]

Kalkis, H., Roja, Z., Vaisla, G., y Roja, I. (2020). Causes of Work Related Musculoskeletal Disorders in the Textile Industry. En W. Karwowski, R. Goonetilleke, S. Xiong, R. Goossens y Murata, A. (Eds.), Advances in Physical, Social & Occupational Ergonomics. AHFE 2020. Advances in Intelligent Systems and Computing, 1215, 63-70. https://doi.org/10.1007/978-3-030-51549-2_9 [ Links ]

Litardo, C. A., Díaz, J. R., y Perero, G. A. (2020). La ergonomía en la prevención de problemas de salud en los trabajadores y su impacto social. Revista Cubana De Ingeniería, X(2), 3-15. [ Links ]

Ministerio de Economía y Finanzas. (2016). Pauta metodológica para la elaboración de planes de negocio de confecciones textiles en el marco de la Ley PROCOMPITE. https://www.mef.gob.pe/contenidos/inv_publica/docs/procompite/2016/plan_negocio/Pauta_planes_de_negocio_confecciones_textiles.pdf [ Links ]

Miranda, B., y Sáenz, L. A. (2020). Método Ergonómico para el Rediseño de Estaciones de Trabajo para Reducir los TME en las empresas PyME del Sector Textil. (Tesis de pregrado). Universidad Peruana de Ciencias Aplicadas, Lima. https://repositorioacademico.upc.edu.pe/handle/10757/651700 [ Links ]

Nabi, M. H., Kongtip, P., Woskie, S., Nankongnab, N., Sujirarat, D., y Chantanakul, S. (2021). Factors Associated with musculoskeletal Disorders Among Female Readymade Garment Workers in Bangladesh: A Comparative Study Between OSH Compliant and Non-Compliant Factories. Risk Management and Healthcare Policy, 14, 1119-1127. https://doi.org/10.2147/RMHP.S297228 [ Links ]

Puig, V., Gallego, Y., y Moreno, M. (2020). Prevención de Trastornos Musculoesqueléticos mediante la mejora de Hábitos Posturales: experiencia en el colectivo de limpieza.Archivos de Prevención de Riesgos Laborales,23(2), 164-181. https://dx.doi.org/10.12961/aprl.2020.23.02.04 [ Links ]

Quiroz, J. C., Aquino, D. M., Rodriguez, E. A., y Montoya, M. F. (2021). Redesign of Workspace through an Ergo-Lean Model to Reduce Musculoskeletal Disorders in SMEs in the Clothing Accessories Sector. International Journal of Engineering Trends and Technology, 69(12), 163-174. https://doi.org/10.14445/22315381/IJETT-V69I12P219 [ Links ]

Sakthi Nagaraj, T., Jeyapaul, R., y Mathiyazhagan, K. (2019). Evaluation of ergonomic working conditions among standing sewing machine operators in Sri Lanka. International Journal of Industrial Ergonomics, 70, 70-83. https://doi.org/10.1016/j.ergon.2019.01.006 [ Links ]

Shahbazi, A., Mokhtarinia, H. R., Biglarian, A., y Gabel, C. P. (2020). The Prevalence of Musculoskeletal Symptoms in Iranian Spinner Workers in the Textile Industry and its Association with Demographic and Lifestyle Characteristics. Iranian Rehabilitation Journal, 18(4), 395-404. https://doi.org/10.32598/irj.18.4.919.2 [ Links ]

Siddiqui, L. A., Banerjee, A., Chokhandre, P., y Unisa, S. (2021). Prevalence and predictors of musculoskeletal disorders (MSDs) among weavers of Varanasi, India: A cross-sectional study. Clinical Epidemiology and Global Health, 12. https://doi.org/10.1016/j.cegh.2021.100918 [ Links ]

Stack, T., Ostrom, L. T., y Wilhelmsen, C. A. (2016). Occupational Ergonomics: A practical approach. Hoboken, NJ, EE. UU.: John Wiley & Sons. [ Links ]

Received: May 03, 2022; Accepted: June 29, 2022

text in

text in