1. Introduction

In the structure of many natural and processed foods, emulsions occur partially or completely; however, some foods are emulsified by certain pro duction steps (Serdaroglu et al., 2015). Emulsions can be easily classified according to the spatial dis tribution of the oily and aqueous phases. A system composed of oil droplets dispersed in the aqueous phase is called oil-in-water (O/W) emulsion, such as milk, cream, dressings, mayonnaise, beverages, soups, and condiments. A system composed of water droplets dispersed in an oil phase is called water-in-oil (W/O) emulsion, such as margarine and butter (McClements, 2015). According to their ap plication two types of emulsions can be formulated single and double emulsions, also according to the size (or diameter) of the droplets are classified into macroemulsions (0.1 to 100 µm), nanoemulsions (10 to 100 nm) and microemulsions (5 to 50nm) and helps us in the determination of their physical and thermodynamic properties (Serdaroglu et al., 2015).

The term 'nano' means smaller particles than 'micro', although microemulsions have smaller droplet sizes since the use of this term predates the use of nanoemulsions. The droplet size in a nanoemulsion determines its optical property and stability and influences its rheological property such as viscosity, solid viscoelasticity, viscoelasticity, solid elasticity, and plasticity based on the composition, droplet size, structure, and interaction between the oil and water phases, emulsifiers, and surfactants (Kumar & Kumar, 2022).

The purpose of emulsion science in the food indus try is to contribute to the development of produc tion techniques and food quality by benefiting from the principles of emulsion used as a vehicle to encapsulate and release bioactive agents, such as vitamins and nutraceuticals (Tan & McClements, 2021) so researchers are trying to develop structured emulsions that can be economically produced using food grade ingredients, with ideal quality attributes, that can control the release of certain ingredients, reduce the total fat content of foods or avoid ingredient interaction.

Various programs at the global and regional level aim to promote healthy eating due to the relation ship with various cardiovascular diseases, chronic respiratory diseases, cancer, diabetes and mental health disorders (OMS, 2014). Obesity and diabetes can be prevented through a multisectoral effort that simultaneously includes several sectors that pro mote the production, distribution and marketing of healthier foods (WHO, 2014), which is why the food industry is looking for new ways to offer products nutritious, either through additions, reductions or substitutions of ingredients. Replacement of animal fats with vegetable, fish and microalgae oil have been studied in products such as hamburgers, sau sages, and meat systems, in order to improve the lipid profile and reduce saturated fat. There is also interest in the use of encapsulated bioactive com pound aggregates in yogurts, cheeses, vegetable foods and beverages to include them in the consumer's diet. This article reviews, analyzes and recapitulates research on food emulsions: meat, dairy, and vegetable emulsions to obtain a broad view of the use of single and double emulsions (DE) in the development of new emulsified food prod ucts with high quality and nutritional characteristics required by today's consumers.

2. Emulsions, types and classification

Emulsion

An emulsion is composed of two immiscible liquids (usually oil and water), one of which is dispersed into the other in the form of small spherical droplets by mechanical shear force and surfactant action (Kale & Deore, 2016). The droplets formed in the emulsion are referred to as the dispersed, discontinuous, or internal phase and the substance forming the surrounding liquid is referred to as the continuous or external phase (McClements, 2015).

Three major components, such as water or an aqueous liquid, oil or oleaginous liquid, and an adequate emulsifier are required for emulsions. The emulsifier may be a low-molecular-weight surfactant, protein, peptide, or lipid. The percentage of emulsifier added to an emulsion is critical for the formation of small-sized droplets as it decreases the interfacial tension (the surface energy per unit area) between the oil and water phases (Kumar & Kumar, 2022).

Emulsion formation does not occur spontaneously under normal conditions. The process of converting two immiscible liquids into an emulsion or reducing the droplet size in a pre-existing emulsion is called homogenization, which is carried out by high-energy methods employing mechanical equipment to form small droplets by subjecting both phases to destructive forces, high-speed stirrers, high-pressure valve homogenizers (HPH), colloid mills, High-pressure microfluidic homogenization (MFH), Rotor-stator homogenization and Ultrasonic ho mogenization (USH) are commonly used (McClements, 2015; Wang et al., 2015). On the other hand, there are low-energy homogenization meth ods, among which are membrane emulsification, micro- and nanochannel emulsification, phase in version emulsification: Phase inversion temperature (PIT), Phase inversion composition (PIC), Emulsion inversion point (EIP), Spontaneous emulsification, Membrane emulsion, etc. (Salvia-Trujillo et al., 2016).

Emulsions can be prepared according to the physi cal and chemical properties of the emulsifier (Wang et al., 2015). In most foods, the droplet diameter is usually between 100 nm and 100 µm. However, due to their physical and chemical properties, there is recent interest in using emulsions with a smaller di ameter (d <100 nm) (McClements, 2015), especially nanoemulsions have broad applications in the food industry such as in quality enhancement and shelf-life improvement of bakery products, dairy prod ucts, meat products, fruit and vegetable products, and also in probiotics and nutraceuticals (Kumar & Kumar, 2022).

Types

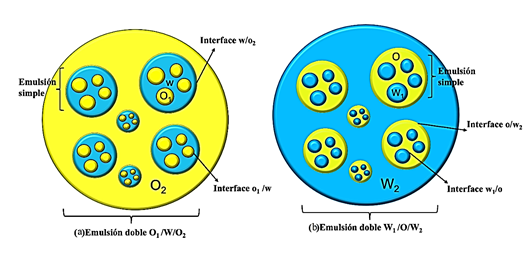

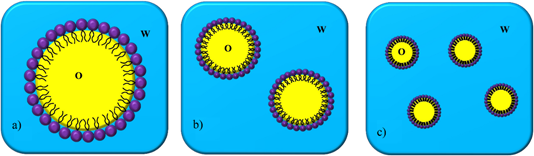

Emulsions are divided into two types: single or conventional and multiple or double (Freire, 2018b). Simple emulsions are those of oil-in-water (O/W) and water-in-oil (W/O) composition, while multiple or double emulsions (DE) are classified into water-in-oil-in-water (W1/O/W2) and oil-in-water-in-oil (O1/W/O2) (Wang et al., 2015), whereby the dispersed droplets contain smaller droplets of different phase (Aserin, 2007). In the latter type, the inner phase is an O1/W emulsion where a hydrophilic surfactant is at its interface that is dispersed in the outer lipid phase (O2) containing a hydrophobic emulsifier at the W/O2 interface to stabilize it (Figure 1a). On the other hand, in the W1/O/W2 system the internal phase is constituted by a W1/O emulsion and a hydrophobic emulsifier at its interface in turn everything is contained in an external aqueous phase (W2) where the hydrophilic surfactant is at the O/W2 interface (Figure 1b) (Freire, 2018b).

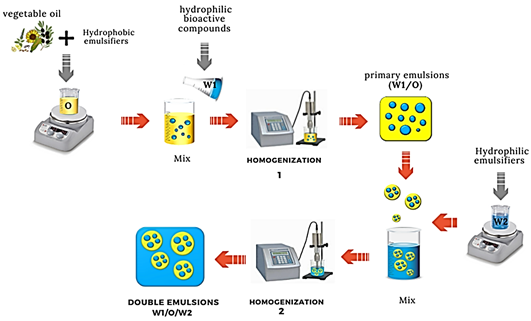

The formation of a DE occurs in two stages (Figure 2). First, the internal emulsion (W1/O) is created, and in a second stage, it is disseminated in the external aqueous phase (W2) (Kumar et al., 2022). Food grade double emulsions can be used in a variety of applications, where the encapsulation of bioactive compounds is one of the most common applications, including the encapsulation of phytochemicals such as quercetin, iron, peptides, etc. (Kumar et al., 2022).

The presence of at least two emulsifiers with different hydrophilic-lipophilic balances to stabilize different water-oil interfaces and the difference in osmotic pressure between the two aqueous phases make double emulsions more difficult to stabilize than single emulsions (Øye et al., 2023).

Table 1 Some thermodynamic and physicochemical properties of emulsions

| Conventional emulsions | Nanoemulsions | Microemulsions |

|---|---|---|

| Drops 0.1 to 100 µm | Drops 10 to 100 nm | Particles 5 to 50 nm |

| Optically opaque | Optically clear or slightly cloudy | Optically clear or transparent |

| Require vigorous homogenization (γi > 10 mN/m) | Low-energy formation (γi < 1 mN/m) | They are formed spontaneously or with lower energy. (γi < 1 mN/m) |

| Kinetically stable for a limited time limited, and thermodynamically unstable | Kinetically stable thermodynamically unstable | Kinetically and thermodynamically stable |

| Low surfactant/phase ratio dispersed (< 1:10) | Intermediate ratio Surfactant/dispersed phase (≈1:1) | High surfactant/phase ratio dispersed (> 1:1) |

| High interfacial area (3 m2/g) | High interfacial area (30 m2/g) | Very high interfacial area (300 m2/g) |

| High viscosity | Low viscosity | Low viscosity (around 1 cP at ambient temperature) |

| High cost of preparation | Low cost of preparation | High preparation cost |

Source: (Kale & Deore, 2016) and (Serdaroglu et al., 2015).

Note: γi: interfacial tension.

Figure 3 Schematic representation of a) macroemulsion, b) nanoemulsions and c) microemulsions with a similar structure: hydrophobic internal phase and hydrophilic external phase.

In contrast to W1/O/W2 emulsions, less research has focused on O/W/O emulsions, however, Zhi et al. (2022) indicate that they can be used to fabricate healthy products by replacing the traditional W/O emulsion with the equivalent O/W/O emulsions, with a lower content of saturated fatty acids and a similar perceived texture in-mouth. Besides the O/W/O emulsions allow to protect and encapsulate sensitive oil-soluble ingredients (such as essential oils and bioactive components) and control the release or delivery of these ingredients during consumption or digestion.

Classification

Droplet size (diameter) is a characteristic feature to classify emulsions into macroemulsions or conventional emulsions, nanoemulsions and microemulsions (Figure 3a, 3b and 3c), furthermore it helps in the determination of their physical and thermodynamic properties (Serdaroglu et al., 2015). Therefore, droplet size and distribution can determine the shelf-life stability, rheological properties, and organoleptic characteristics such as color and flavor of food emulsions (Wang et al., 2015).

Microemulsions and nanoemulsions are increasingly used in the food and pharmaceutical industries to encapsulate, protect, and deliver bioactive, lipophilic components, vitamins, antioxidants (McClements, 2012), oil soluble flavors, vitamins and nutraceuticals (Wang et al., 2015). Both possess water, surfactant ingredients and components in their composition and the droplet size can be considered similar (Kale & Deore, 2016; Wang et al., 2015). However, nanoemulsion is formed by mechanical force and microemulsion is formed by selfassembly (Serdaroglu et al., 2015), this is because a microemulsion is thermodynamically stable, while a nanoemulsion is not (McClements, 2012) (Table 1).

3. Stabilization Mechanisms of Emulsion

Because of their structure, emulsions are usually thermodynamically unstable, mainly in DE (O/W/O), so instability phenomena can occur in both internal and external emulsions. The instability of emulsions occurs in four forms: Flocculation, Coalescence, Sedimentation or creaming and Ostwald Ripening. Flocculation occurs when several droplets tend to move toward each other because of the attractive forces (Van der Waals interactions) and then increase in droplet size of the dispersed phase, therefore accelerating the coalescence.

Coalescence occurs after flocculation; droplets irreversibly merge resulting in the production of larger droplets that will eventually be separated into two phases. Sedimentation or Gravitational separation occurs when gravity affects the migration of the dispersed phase of an emulsion, making resulting in sedimentation or creaming. Level of sedimentation is directly associated with droplet size and the density difference between the dispersed and continuous phases. Creaming happens when the interfacial membrane between droplets can rupture and cream irreversibly (Kumar et al., 2022). Finally, the Ostwald Ripening occurs when environmental parameters, such as temperature and ionic strength change, and produce small droplets with a large curvature dissolve faster than the large droplets with a small curvature. Thus, the small droplets tend to diffuse and deposit on the interface of larger droplets. The difference in solubility between dispersed emulsion droplets is driving by Ostwald ripening force (Zhi et al., 2022).

The stabilization of the emulsions is achieved by adding macromolecules (synthetic surfactants, biopolymers such as proteins, polysaccharides and their mixtures), by stabilizing the viscosity through the use of polysaccharides such as xanthan gum, starch, among others (Zhi et al., 2022) and by adding solid particles such as paraffin, triacylglycerols, polymers, clay, rice husk silica to produce DE (W1/O/W2) generating a relatively high stability, reducing the use of synthetic polymeric surfactants and the fat fraction incorporated in processed foods could be reduced considerably (Sapei et al., 2022). These solid particles can generate a network and be adsorbed at the interface between different phases, providing a physical barrier to inhibit fusion. This type of stabilization mechanism is called Pickering stabilization while the emulsions prepared are called Pickering emulsions.

4. Main applications of food emulsions

In this section are the main food applications using the emulsions. Recent research applied to developing products with nutritional, technological and functional profile according to the new requirements by consumers is described. Emulsion-based delivery systems are widely used for the delivery of lipophilic nutraceutical foods due to their ease of formulation and manufacture (Zhang et al., 2023)

5. Innovations in meat products and derivatives

Research in the meat industry on single and double emulsions (Table 2) has been carried out in order to improve the lipid profile (Bernardi et al., 2016), reduce saturated fat content, improve oxidative stability (thiobarbituric acid (TBARS)) during storage, improve their functional properties by incorporating healthy substances (antioxidants, bioactive compounds and oils rich in omega-3 fatty acids) (Toldrá & Reig, 2011), improve water holding capacity (WRC) as well as in technological stability (lower percentage of fluid and fat expelled) seeking to maintain their organoleptic characteristics and consumer acceptability (Öztürk et al., 2016).

Simple emulsions used in meat formulations include gelled (O/W) type emulsions. The use of chia flour and oat bran with water in the (W) phase and olive oil in the (O) phase to replace animal fat in the formulation of fresh sausages have been reported (Pintado et al., 2018); the use of tiger nut (Cyperus esculentus L.) as a beef fat substitute for the preparation of hamburgers (Carvalho et al., 2020), the use of a hazelnut oil-based emulsion as an animal fat replacement in the formulation of beef sausages (Urgu-Öztürk et al., 2020), as well as the use of chia mucilage and olive oil as a substitute for up to 20% pork fat in the preparation of bologna sausages (Ferreira et al., 2021) obtaining in all cases a positive effect in the reduction of saturated fatty acids (SFA), an increase of monounsaturated fatty acids (MUFA) and polyunsaturated fatty acids (PUFA) and general acceptance without significant deference in organoleptic characteristics such as texture, color. Furthermore, Wang et al. (2018) used a Pickering emulsion based on cellulose nanofibers and were able to decrease the fat content in sausages (Klojdová & Stathopoulos, 2022).

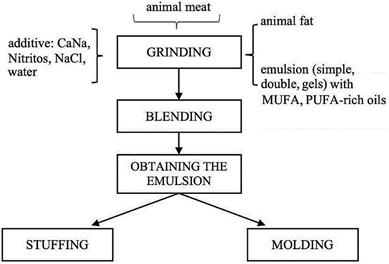

For the formulation of a meat system, the formation of a DE is carried out in two stages with partial aggregation in replacement of animal fat (Figure 4). In reformulated frankfurters using perilla (Perilla frutescens) oil by means of DE (W1/O/W2) in replacement of pork back fat, an increase in the proportion of PUFA from 0.4g/100 (control) to 55. 1 g/100 g (reformulated), reduce the content of total SFA from 40.9% (control) to 11.6% (reformulated); while the taste, texture and overall acceptability is lower compared to the control formulation (content 21% pork back fat) (Freire et al., 2016). In meat systems using DE (W1/O/W2 double emulsion) based on olive leaf extract (Olea europaea) in the internal phase (W1) and a mixture of healthy oils (olive, linseed and fish; 7:2:1) as lipid phase (O) a product with antioxidant capacity (>80%) is achieved in 14 days of storage at 4°C, reduction of SFA by 15% and increase of PUFA content (about 10%) as well as a more balanced ω-6/ω-3 fatty acid ratio (about 0. 8%) (Robert et al., 2018).

Other important characteristics in the incorporation of a fat substitute are cooking yield and toughness, which improve with the incorporation of a DE (W1/O/W2). In the breading of chicken meat refor mulated with a DE with berry extract (Murraya koenigii) as the internal phase and soybean oil as the external phase, an increase in cooking yield and a decrease in toughness are achieved by increasing its chewiness (Kumar & Kumar, 2020). Likewise, simple emulsion gels used as fat substitutes that include in the internal lipid phase ω-3 fatty acids (olive oil, flaxseed, fish) and condensed extracts in the gelation (Freire et al., 2018a), improve the softness values while maintaining acceptable sensory characteristics of chicken sausages (Kavuşan et al., 2020). The use of nanoemulsions allows controlling microbial growth, inhibits lipid oxidation, improves sensory properties, and prolongs shelf life. Moraes-Lovison et al., (2017) used a nanoemulsion of oregano essential oil (5%) prepared with water and emulsifier [cremophor RH 40 (12%) and Span 80 (8%)] to add to chicken pate. Microbial reduction of 1 log cycle of S. aureus and 2 log cycles for Escherichia coli was observed within 6 h of application was achieved (Kumar & Kumar, 2022).

An alternative to the use of vegetable oils in the preparation of emulsions is oils from microalgae. It has been demonstrated that the addition of an extract rich in antioxidants from the edrinum branch (Prunus spinosa L.) in an emulsion formulated with microalgae oil as a source of fat replacement in meat patties allows obtaining product with low fat content (5.2%) compared to a meat patty (10.6%), an increase of docosahexaenoic acid (DHA) (greater 50%) and a 53% reduction of SFA versus the control, in addition to not significantly affecting its sensory characteristics (Alejandre et al., 2018).

Table 2 Summary of strategies for incorporating emulsion systems in meat systems

| Incorporation strategy | Oil in emulsion | % PEF | Meat product | CI SFA (%) | CF SFA (%) | Reference |

| W1/O/W2 | Perilla oil | 30% | Frankfurter sausage | 40.9 | 11.6 | Freire et al. (2016) |

| W1/O/W2 stabilized with freeze-dried egg white | Olive Oil | 10% (E10), 20% (E20) y 30% (E30) | Meat emulsion model system | 50.2 | 10.9 (E30) | Öztürk, et al. (2016) |

| O/W gelled emulsion with edrin branch extract | Microalgae oil (Crypthecodinium cohnii) | 20% | Hamburger | 53% reduction of SFA | Alejandre et al. (2018) | |

| O/W gelled emulsion with chia flour and oat bran | Olive Oil | 27% | Fresh sausage | 12.3 | 2.85/2.9 | Pintado et al. (2018) |

| O/W gelled emulsion with condensed tannin extract | Olive, flaxseed and fish oil | - | Meat emulsion model system | - | - | Freire et al., (2018a) |

| W1/O/W2 with olive leaf extract in W1 | Blend of oils: olive, flaxseed and fish oils | 10% | Meat emulsion model system | 37 | 20.6 | Robert et al., (2018) |

| W1/O/W2 with Murraya koenigii berry extract in W1 | Soybean oil | 20% | Model meat system | Not calculated | Not calculated | Kumar & Kumar (2020) |

| O/W pre-emulsion | chufa oil (Cyperus esculentus L.) | 50% (TN50, 100% (TN100) | Hamburger | 42.9 | 38.6 TN50, 33.4 TN100 | Carvalho et al. (2020) |

| O/W pre-emulsion with hazelnut flour | Hazelnut oil | 50% y 100% | Sausage | 47.2 | 13.6 | Urgu-Öztürk et al. (2020) |

| O/W gel emulsion | Linseed oil | 50%, 75%, 100% | Sausage | 15.5 | 9.9 | Kavuşan et al., (2020). |

| O/W gelled emulsion with chia mucilage | Olive oil | 20% | Bolonia Sausage | 43.2 | 22.9 | Ferreira et al. (2021) |

| W1/O/W2 | Soybean oil | 10%, 20% ,30% | Sausage | 36.2% | 22.9 (10%), 16.7 (20%), 17 (30%) | Zheng et al. (2023) |

Note: PEF: Percentage of emulsion in the formulation; CI SFA: Initial content of saturated fatty acids in the control formulation; CF SFA: Final content of saturated fatty acids in reformulated products; SFA: Saturated fatty acids; E10, E20 and E30: (10%, 20% and 30% of double emulsion used in the formulation of the model meat emulsion system, respectively), TN50 and TN100: (50% and 100% of beef fat replaced by tiger nut oil, respectively).

6. Innovations in dairy products

Current healthy eating requirements have promoted dairy product innovation using single and double emulsions as a means of delivering bioactive compounds, in the encapsulation of microorganisms or in the delivery of micronutrients such as vitamins and iron allowing their controlled delivery and increased bioaccessibility during digestion (Saffarionpour & Diosady, 2021).

Single emulsions (O/W) have been used for the encapsulation of vitamin D3 (cholecalciferol) and PUFAs in the development of cheddar cheeses (Stratulat et al., 2015), whole milk fortification (Golfomitsou et al., 2018), yogurt, ice cream, and butter, obtaining products with improved nutritional value (Table 3), good yield, stability during storage (Kumar & Kumar, 2022), as well as acceptable sensory properties. The formation of nanoemulsions is carried out using emulsifiers (such as polysorbate and soy lecithin) and by high-pressure homogenization, oil droplets with mean diameters < 200 nm are generated and vitamin D3 is incorporated to encapsulate it and then enrich food matrices, remaining stable upon gravitational separation.

An omega-3 algal oil nanoemulsion was used in yogurt formulation to evaluate the bioavailability and absorption of long-chain omega-3 polyunsaturated fatty acids (LC3 PUFA), resulting that the level of LC3 PUFA was 1.78 and 1.62 times higher after 4 and 6 h of ingestion of formulated yogurt (Lane et al., 2014). Yogurt fortified with nanoemulsion had similar body, taste, and appearance characteristics to plain yogurt (Kumar & Kumar, 2022).

Mohammed et al. (2020) formulated stable nano-emulsions (188.4 nm) using 10% Nigella sativa oil with gum arabic (GA) (0.64%w/p), sodium ca seinate (6.49%w/p) and Tween 20 (2.87%w/p) by high-pressure homogenization processes at a pres sure of 22,000 psi during 5 cycles, and then added to ice cream at 0, 3, 5 and 10%, and its effect on textural and sensory properties was studied, result ing that with a substitution of 5% an ice cream with firmness and consistency equivalent to the control as well as an acceptable flavor is obtained. In addi tion, low-fat ice creams have been developed without flavor or texture compensation through the nanoemulsion process and have been commercially produced by Nestlé and Unilever (Kumar & Kumar, 2022).

The application of single emulsions also includes their use in the formulation of low-fat foods with antimicrobial properties. Artiga-Artigas et al. (2017) used nanoemulsions containing 2.5% (w/w/p) oregano essential oil were prepared using 2.0% (w/w) sodium alginate, 0.5% (w/w) mandarin (Citrus reticulata) fiber and 2.5% (w/w) Tween 80, for use as an antimicrobial coating on low-fat cheese, successfully reducing the Staphylococcus aureus population from 6.0 to 4.6 log CFU/g after 15 days of storage at 4 °C (Kumar & Kumar, 2022). Partial replacement of butter with cinnamon essential oil in zein-stabilized pickering emulsions improved the nutritional value and facilitated better control of mold growth in food products (Klojdová & Stathopoulos, 2022).

Other applications of nanoemulsions from essential oils (basil, cinnamon, citrus, rosemary and oregano, sesame and thyme) are used as browning reducer (by inhibiting polyphenolic activity), inhibitor of fungal pathogens (Penicillium chrysogenum and Aspergillus flavus ), molds and yeasts, antibacterial capacity (E. coli , Listeria monocytogenes, S. aureus and Salmonella spp.) and prolonging the shelf life of fresh foods such as: okra pods (Abelmoschus esculentus), apples, apple and orange juice, fresh celery, cherry tomatoes, among others (Kumar & Kumar, 2022).

Numerous investigations employ DE (W1/O/W2) to incorporate encapsulated bioactive compounds in the formulation of yogurt, cheddar cheese, skim milk, milk-based desserts, and ice cream products, and then evaluate their feasibility as well as technological, microbiological, sensory, physicochemical, and nutritional changes. In greek style yogurt, DE increases its acidification kinetics, improves WRC and increases its viscosity (Lalou et al., 2017). Cheeses formulated with DE fortified in the W1 internal phase with rice protein (RP), pumpkin seed protein (PSP) or whey protein isolate (WPI) achieve fat percentage reduction (between 16% and 20%) and higher protein content (Paximada et al., 2020). In the case of ice cream, the fat content is 10% to 12%, which can be replaced up to 80% by various oligosaccharides (as prebiotics) using DE (Yildirim et al., 2016; Kumar et al., 2022).

Also, the phase of incorporation of bioactive compounds in DE affects the sensory characteristics and stability of the dairy product, since controlled release and better masking is possible offering better sensory characteristic of the product (Herzi & Essafi, 2020). Simiqueli et al. (2019) demonstrated that the insertion of iron sulfate (FeSO4) in the internal phase of DE (W1) in a milk dessert increases the sensory perception of undesirable changes, while the insertion in the external phase (W2) allows the addition of higher concentration of FeSO4, without compromising sensory acceptability and avoiding consumer rejection. In contrast, vitamin B12 is better masked in the internal phase (W1) (Zaghian & Goli, 2020).

Table 3 Summary of strategies for incorporating emulsion systems in dairy products and derivatives

| Incorporation strategy | Masking compound | % of use | Dairy product | Reference |

| W1/O/W2 | Sunflower oil in the oil system | 33% | Yogurt type set | Lalou et al. (2017) |

| W1/O/W2 | Lactobacillus paracasei probiotic | 33% | Yogurt type set | El Kadri et al. (2018) |

| W1/O/W2 with sunflower oil as (O) | Magnesium chloride | 7% | Yogurt | Pintado et al. (2018) |

| W1/O/W2 | Fish protein hydrolyzate | 2% | Yogurt | Jamshidi et al. (2019) |

| W1/O/W2 lyophilized | (PR), (PSP) y (WPI) | 5% | Cheddar cheeses | Paximada et al. (2020) |

| W1/O/W2 with sunflower oil | Vitamin B12 | 1% | Skimmed milk | Zaghian & Goli (2020) |

| W1/O/W2 | Whey protein concentrate (WPC) | 10%, 15% | Model cheese matrices | Gamlath et al., (2023) |

Rice protein (RP) and pumpkin seed protein (PSP) and milk protein: whey protein isolate (WPI).

El Kadri et al. (2018) evaluated the viability of probiotic L. paracasei. encapsulated in the internal phase (W1) at simulated gastrointestinal (GI) conditions found a high survival rate, likewise the textural properties (firmness) during storage were better with stability in oil globules during 28 days of storage. It was verified the stability of a rich yogurt formulated with DE loaded with bioactive compounds (Polyphenols, vitamins C, B9 and B12) in the internal phase; and vitamins A and D in the oil phase) after 20 days of storage. Even the canning-type yogurt formulated with DE in the internal phase (W1) maintained its structural stability during its storage period (Lalou et al., 2017).

Jamshidi et al. (2019) optimized the encapsulation of fish protein hydrolysate (W1) and fish oil (O) in a complex of whey protein concentrate (WPC) and inulin (W2). By means of this DE (W1/O/W2) natural yogurt was enriched with optimally formulated microcapsules and an ideal DE formulation was found (2:1 ratio of W2/, W1/O; 2.12:1 ratio of WPC/ inulin in W2 and 6.28% of polyglycerol polyricinoleate (PGPR)); also the most important variable was the ratio of WPC/Inulin, resulting by increasing it, the stability and cream index increase and the efficiency decreases. For its sensory evaluation, the optimized formula was freeze-dried and added to cold milk for its subsequent elaboration of fortified yogurt. The sensory evaluation had no visual effect, but it influenced the flavor, due to the nature of the fish, so it is recommended to use additives to improve this problem.

7. Application of emulsions of vegetable origin and as a nutrient supply

Natural emulsifiers of plant origin are aligned with the current trend and new requirements of vegan and vegetarian products using sustainable ingredients, due to this they are gaining more interest in the global market, the scientific community, and the food industry (Santamaria-Echart et al., 2021). The use of emulsifying agents such as GA, beet pectin, corn fiber gum and ginseng sapononins (Shu et al., 2018) in the aqueous phase of simple emulsions has been investigated to compare the droplet size and interfacial tension that promote emulsion stability during storage (Bai et al., 2017).

Proteins of vegetable origin can be considered as an option for emulsification or stabilization. Proteins from legumes such as soybean, pea, chickpea, lentil, flaxseed, bean, and some species of the Amaranthaceae and Polygonaceae family such as amaranth, buckwheat and quinoa-derived proteins have been used as emulsifiers (Lingiardi et al., 2022). Peng et al. (2022) used soy proteins, sodium caseinate and flaxseed protein as emulsifiers, and observed that the latter show higher emulsifying property in terms of emulsifying activity index and emulsion stability index, it has also been reported that the emulsion prepared with flaxseed protein concentrate exhibits rheological behaviors of shear and non-Newtonian fluidization. Flaxseed protein concentrates containing different levels of mucilage have good emulsifying activity and stability compared to soy protein. Some research aimed to improve the emulsifying and foaming behaviors of flaxseed protein by modifications such as physical treatment (e.g., ultrasonic field, plasma treatment) and complexing with polysaccharides or polyphenols.

Simple emulsions based on vegetable oils and proteins (pea protein, soy protein) (Francisco et al., 2020), potato protein concentrate (PPC) (Galves et al., 2021) are used for their effectiveness for the encapsulation by atomization of bioactive compounds and then characterize the physicochemical, morphological properties, in vitro bioactivity, antioxidant capacity by ferric reducing antioxidant power (FRAP) analysis, oxygen radical absorbance capacity (ORAC), among others (Felix et al., 2019) of the microparticles. Physical (such as spray drying, freeze drying, fluid bed drying, etc.) and chemical (such as emulsification, coacervation, etc.) encapsulation techniques are specifically suitable for developing bioactive compounds from fruits, vegetables, or other plant materials (Kumar et al., 2022).

During encapsulation, a single emulsion is usually unstable and has limited ability to encapsulate water-soluble compounds. In contrast, DE can encapsulate both hydrophilic and hydrophobic compounds; as they are a complex system, where the droplets of the dispersed phase contain one or more types of smaller dispersed droplets (Tyowua et al., 2017). Numerous studies are available on the encapsulation of bioactive compounds by double emulsions (Table 4). For example, trans-resveratrol (3,5,4-trihydroxystilbene) is a major polyphenol in wine that has potential antioxidant, anti-inflammatory, and antitumor properties. It is readily oxidizable, photosensitive, has low water solubility and therefore has a short biological half-life. Encapsulation of this polyphenol by double emulsion technique has potential to overcome these limitations (Matos et al., 2018; Kumar et al., 2022).

Other encapsulated plant-derived bioactive compounds that have used DE in their internal phase are antiocyanins (Liu et al., 2019), phenolic compounds from extracts of non-edible parts of plants, and agro-industrial waste (Velderrain-Rodríguez et al., 2019). Then evaluate the encapsulation efficiency, appearance and particle size, stability during storage, release rate by varying the composition of the oil phase as it affects the droplet size (Chouaibi et al., 2018), in addition, the volume fraction of oil in emulsions is a variable to determine the release kinetics and it turns out that the lower the fraction the higher the release (Snoussi et al., 2020).

The use of double emulsions has favored the protection, masking as well as stability of the encapsulates added in beverages. Aditya et al. (2015) obtained a DE (W1/O/W2) using catechin as the internal phase and curcumin extract in its oil phase and found a significant increase in the stability of both encapsulated bioactive compounds in beverage formulations after 15 days of storage; likewise, using pectin-protein biopolymers in the external phase (W2) obtained better results in the retention of saffron bioactive compounds (crocin, safranal and picrocrocin) achieving better retention stability after 22 days of storage (Faridi et al., 2017).

For fortified vegetable food emulsions formulation, presenting a texture like whipped cream, Rando et al. (2022) studied the partial coalescence process in DE (W1/O/W2) and single (O/W2) calcium-fortified emulsions was prepared with soybean flour in aqueous dispersion in the continuous phase (W2) and vegetable fat including PGPR as lipophilic emulsifier in the lipid phase. Encapsulated calcium chloride was added in the aqueous dispersed phase (W1) and in the W2 phase of W1/O/W2 and O/W2 emulsions, respectively. It was concluded that the addition of calcium leads to more stable emulsions, attributed to increased globule aggregation. Besides, the W1/O/W2 emulsions exhibited high stability of rheological properties. Thus, the rheological characteristics could be adjusted by controlling calcium release and PGPR concentration.

Table 4 Summary of strategies for incorporation of emulsion systems with incorporation of plant-derived compounds

| Incorporation strategy | W1: Masking compound | O: Oily phase | W2 | Reference |

| W1/O/W2 | Curcumin + catechin | Olive, soybean and sunflower oil +PGPR | Water, Tween 80, NaCl and Vitamin C | Aditya et al. (2015) |

| W1/O/W2 | Saffron extract | Sunflower oil + span 80 | pectin-protein | Faridi et al. (2017) |

| W1/O/W2 | Quercetin | Olive, red bell pepper and sunflower oils + PGPR | Water + pectin + sodium caseinate | Chouaibi et al. (2018) |

| W1/O/W2 | Resveratrol | Neutral oil | Tween 20 + sodium carboxymethylcellulose (CMC) | Matos et al. (2018) |

| W1/O/W2 | Anthocyanin (carrot) | Corn oil | Quillaja saponin | Liu et al. (2019) |

| O/W | Bean protein concentrate (Vicia Faba) | Sunflower oil | - | Felix et al. (2019) |

| W1/O/W2 | Phenolic compounds from mango peel extract | Corn oil + PGPR | Tween 20/Tween 80 o Lecitin | Velderrain-Rodríguez et al. (2019) |

| W1/O/W2 | Catequin | Cottonseed oil | Chitosan + CaNa Lactose | Snoussi et al. (2020) |

| W1/O/W2 | Mango seed extract (Mangifera indicaL.) 'Ataulfo' | Canola oil | PVA + mango pulp + water | Martinez et al. (2023) |

PGPR: Polyglycerol polyricinoleate; Tween 80: Polysorbate 80; Tween 20: Polysorbate 20; CaNa: Sodium caseinate; Span 80: Sorbitan monoleate; PVA: Polyvinyl Alcohol.

For the manufacture of low-fat spreads, double O/W/O emulsion system was used using oil-soluble flavors as the inner phase, polysaccharides with a hydrophilic emulsifier as the aqueous phase and edible triglyceride oils derived from seed oils containing emulsifying lipophiles as the outer oil phase (Zhi et al., 2022). Patel (2017) elaborated spreads from sunflower oil in the inner phase, water containing gelling and xanthan gum in the aqueous phase and melted palm oil without or with sunflower oil outer oil phase for possible applications in low fat products.

Finally, nanoemulsions increase the bioavailability of micronutrients and phytocomponents by reducing the particle size, modifying the surface, binding, or trapping the phytocomponent with different micro or nanomaterial polymers, thus increasing its absorption in the simulated gastrointestinal tract. Likewise, probiotic nanoemulsions (single and double) have been developed by using live microorganisms (Lactobacillus delbrueckii ssp. bulgaricuss, Enterococcus faceiumse, Lactobacillus rhamnosus) in the aqueous phase to incorporate them in foods and provide health benefits (Kumar & Kumar, 2022).

8. Current and future challenges

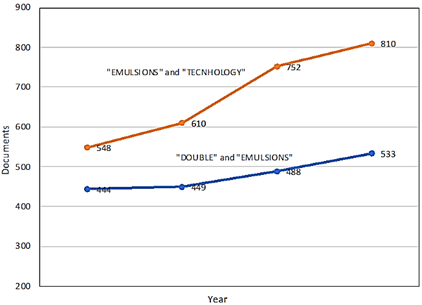

Emulsions are a technology alternative widely used in the food industry for the development of novel food formulations. Food material of natural origin is attracting more attention as people become more conscious of eating nutritious food using sustainably sourced ingredients. Numerous studies have been conducted to evaluate the performance of single and double emulsions for the formulation of meat and dairy foods and the use of various bioactive compounds encapsulated through emulsions. Research suggests that emulsification is an effective process for preparing a variety of natural foods (Figure 5).

Figure 5 Number of publications of the last 4 years (2019 to 2022) found on the Web of Scopus (https://www.scopus.com, 01.04.2023) using the following phrases: ‘double emulsions’ and ‘technology emulsions’.

However, there is still much research to be done in the development of emulsion systems that are compatible with the foods to be reformulated to ensure a better lipid profile, sensory, microbiological, and nutritional stability in accordance with the new preventive trends of healthy eating and compliance with clean labeling claims; and that in turn reach the application at the industrial level.

9. Conclusions

The use of single and double emulsion systems as a substitute ingredient for animal fats is a powerful proposal for the development of nutritious and innovative foods in a healthy diet required by new consumers, especially in the bakery, dairy, meat and fruit and vegetable industries. Therefore, it could be said that emulsions help in the development of products formulated with bioactive compounds and even in the masking of unpleasant flavors and aromas that often present these compounds in such a way that they do not vary drastically in the sensory characteristics in front of consumers; in particular, nanoemulsions allow increasing the bioavailability of nutrients, improving the delivery of bioactive compounds and improving the thermal stability of probiotics and the shelf life of foods.